MES System, a cornerstone of modern manufacturing, empowers businesses to streamline production processes, enhance quality control, and optimize resource allocation. By integrating various functionalities, MES systems provide real-time visibility into every stage of the manufacturing journey, from raw materials to finished goods.

Table of Contents

From scheduling and production tracking to quality management and data analytics, MES systems offer a comprehensive solution for manufacturers seeking to improve efficiency, reduce costs, and gain a competitive edge. Whether it’s in automotive, pharmaceuticals, or electronics, MES systems are transforming industries by enabling data-driven decision-making and driving continuous improvement.

MES System Fundamentals

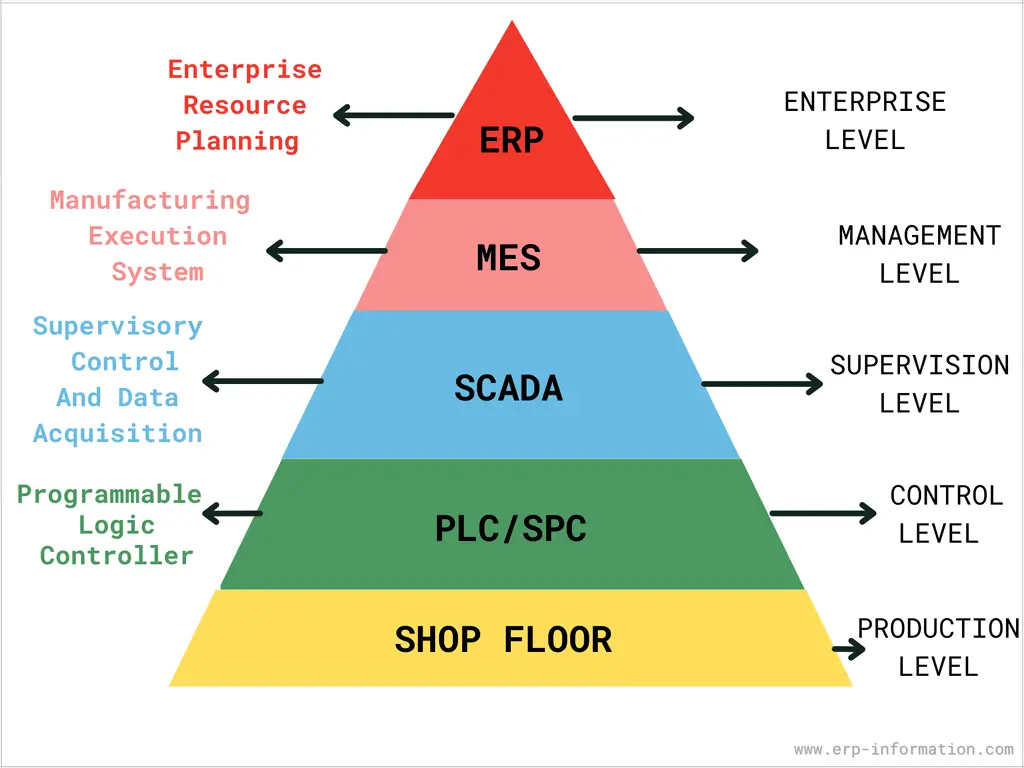

An MES system, or Manufacturing Execution System, is a software solution that plays a crucial role in bridging the gap between a company’s planning and execution processes within a manufacturing environment. It acts as a central hub, collecting and managing real-time data from various sources, including machines, sensors, and workers, to provide visibility and control over the entire production process.

MES System Purpose

MES systems are designed to optimize and streamline manufacturing operations by providing real-time insights and control over various aspects of production. They enhance efficiency, reduce waste, improve quality, and ensure compliance with industry standards.

Core Functionalities of an MES System

MES systems offer a wide range of functionalities that address key aspects of manufacturing execution. These include:

- Production Scheduling and Dispatching: MES systems allow for efficient scheduling of production orders, assigning tasks to specific machines and operators, and monitoring progress in real-time. This ensures optimal resource utilization and timely completion of orders.

- Work-in-Progress (WIP) Tracking: By tracking the movement and status of materials and products throughout the production process, MES systems provide real-time visibility into the location and progress of WIP. This helps in identifying bottlenecks and optimizing material flow.

- Data Collection and Analysis: MES systems collect data from various sources, including machines, sensors, and operators, to provide detailed insights into production performance. This data can be analyzed to identify trends, optimize processes, and make informed decisions.

- Quality Control and Traceability: MES systems enable robust quality control by tracking product attributes, capturing inspection data, and generating reports to identify potential issues. They also provide complete traceability, allowing for the tracking of products from raw materials to finished goods.

- Operator Interface and Communication: MES systems provide user-friendly interfaces for operators, enabling them to access production instructions, monitor machine status, and report issues. They also facilitate communication between operators and management, ensuring smooth workflow and coordination.

- Integration with Other Systems: MES systems can seamlessly integrate with other enterprise systems, such as Enterprise Resource Planning (ERP) systems, supply chain management (SCM) systems, and quality management systems (QMS). This integration enables a holistic view of the entire manufacturing process and facilitates data sharing and collaboration.

Industries Where MES Systems Are Widely Used

MES systems are widely adopted across various industries, including:

- Automotive: MES systems play a crucial role in managing complex production lines, ensuring quality control, and tracking vehicle components.

- Aerospace: The aerospace industry relies heavily on MES systems to manage intricate manufacturing processes, maintain high quality standards, and ensure compliance with stringent regulations.

- Pharmaceuticals: MES systems are essential in the pharmaceutical industry to comply with Good Manufacturing Practices (GMP), track production batches, and ensure product safety and efficacy.

- Electronics: The electronics industry utilizes MES systems to manage high-volume production lines, track component inventory, and ensure product quality.

- Food and Beverage: MES systems are widely used in the food and beverage industry to manage production processes, track ingredients, and ensure compliance with food safety regulations.

Key Components of an MES System

An MES system is comprised of various modules that work together to manage and optimize manufacturing processes. These modules provide real-time data and insights, enabling manufacturers to improve efficiency, quality, and overall production performance.

Essential Modules Within an MES System

The core modules of an MES system provide essential functionalities for managing and controlling manufacturing operations. These modules are interconnected and rely on data exchange to ensure seamless operations.

- Scheduling: This module optimizes production schedules based on factors like available resources, production demands, and material availability. It helps prioritize tasks, allocate resources efficiently, and minimize downtime. For example, a scheduling module can automatically adjust production plans based on machine availability, material delivery times, and customer order deadlines.

- Quality Management: This module ensures product quality by tracking and managing quality data throughout the production process. It includes features for collecting quality metrics, analyzing data, identifying potential issues, and implementing corrective actions. For instance, a quality management module can track defect rates, identify root causes of defects, and generate reports to improve quality control processes.

- Production Tracking: This module monitors the progress of production orders, providing real-time visibility into production status, resource utilization, and material consumption. It enables manufacturers to track production performance, identify bottlenecks, and make informed decisions to optimize production flow. For example, a production tracking module can track the progress of each production step, monitor machine performance, and provide alerts for potential delays or deviations from the planned schedule.

- Work-in-Progress (WIP) Management: This module manages the flow of materials and products through the production process. It tracks the location and status of WIP, ensuring efficient material handling and minimizing inventory build-up. For example, a WIP management module can track the movement of materials between workstations, monitor inventory levels, and provide alerts for potential material shortages or overstock.

- Data Acquisition and Analysis: This module collects data from various sources within the manufacturing environment, including machines, sensors, and other equipment. It analyzes the data to provide insights into production performance, identify trends, and support decision-making. For example, a data acquisition and analysis module can collect data on machine uptime, production output, and energy consumption, providing valuable insights for process optimization and cost reduction.

- Operator Interface: This module provides a user-friendly interface for operators to interact with the MES system. It allows operators to monitor production status, enter data, receive instructions, and report issues. For example, an operator interface can display real-time production data, provide instructions for specific tasks, and allow operators to log production events and report equipment malfunctions.

- Reporting and Analytics: This module generates reports and dashboards to provide insights into production performance, quality metrics, and other key indicators. It helps manufacturers identify areas for improvement, track progress towards goals, and make data-driven decisions. For example, a reporting and analytics module can generate reports on production efficiency, defect rates, and material usage, providing insights for continuous improvement initiatives.

Integration of MES Systems with Other Manufacturing Software

MES systems are often integrated with other manufacturing software to create a comprehensive and interconnected manufacturing ecosystem. This integration facilitates data sharing, improves process efficiency, and enables better decision-making.

- Enterprise Resource Planning (ERP) Systems: Integration with ERP systems allows for seamless data exchange between production planning, inventory management, and financial accounting. This enables manufacturers to track production costs, manage inventory levels, and optimize resource allocation. For example, an MES system integrated with an ERP system can automatically update inventory levels based on production output, track production costs, and generate invoices based on completed orders.

- Product Lifecycle Management (PLM) Systems: Integration with PLM systems provides access to product design data, engineering specifications, and bill of materials. This enables manufacturers to ensure accurate production processes, manage product revisions, and track product quality throughout the lifecycle. For example, an MES system integrated with a PLM system can automatically generate production plans based on product specifications, track changes in product design, and ensure compliance with quality standards.

- Computer-Aided Design (CAD) Systems: Integration with CAD systems allows manufacturers to access product designs and manufacturing drawings directly within the MES system. This facilitates accurate production planning, reduces errors, and improves communication between design and manufacturing teams. For example, an MES system integrated with a CAD system can automatically generate production instructions based on design data, track changes in design, and ensure consistency between design and production.

- Supervisory Control and Data Acquisition (SCADA) Systems: Integration with SCADA systems enables real-time monitoring and control of manufacturing equipment. This allows manufacturers to optimize equipment performance, reduce downtime, and improve production efficiency. For example, an MES system integrated with a SCADA system can monitor machine performance, detect equipment malfunctions, and provide alerts for potential issues. It can also automatically adjust machine settings to optimize production parameters.

Examples of How Different Modules Work Together to Achieve Manufacturing Goals

Different modules within an MES system work together to achieve specific manufacturing goals. For instance, a manufacturer aiming to improve production efficiency might use the following modules:

- Scheduling: The scheduling module would optimize production plans to minimize downtime and maximize resource utilization.

- Production Tracking: The production tracking module would monitor production progress, identify bottlenecks, and provide real-time insights into production performance.

- Data Acquisition and Analysis: The data acquisition and analysis module would collect data on machine performance, identify areas for improvement, and provide insights for optimizing production processes.

- Reporting and Analytics: The reporting and analytics module would generate reports and dashboards to track progress towards efficiency goals and identify areas for further optimization.

Benefits of Implementing an MES System

An MES system offers numerous advantages that can significantly improve a manufacturing operation’s efficiency, quality, and profitability. These systems provide a comprehensive view of the production process, enabling better decision-making, enhanced control, and ultimately, increased productivity.

Enhanced Production Efficiency

Implementing an MES system can significantly enhance production efficiency through several key mechanisms.

- Real-time monitoring and control: MES systems provide real-time visibility into production processes, allowing operators to monitor key performance indicators (KPIs) such as cycle times, machine utilization, and production output. This real-time data enables prompt identification and resolution of production bottlenecks, optimizing resource allocation and maximizing throughput.

- Automated scheduling and dispatching: MES systems automate the scheduling and dispatching of production tasks, ensuring optimal resource utilization and minimizing idle time. This automation reduces manual errors and improves the overall efficiency of the production process.

- Improved communication and collaboration: MES systems facilitate seamless communication and collaboration between different departments, such as production, engineering, and quality control. This streamlined communication enables faster problem-solving and improves overall efficiency.

Improved Quality Control and Product Traceability

MES systems play a crucial role in enhancing quality control and product traceability, ensuring consistent product quality and meeting regulatory requirements.

- Real-time data capture and analysis: MES systems capture real-time data on production parameters, such as temperature, pressure, and material usage. This data can be analyzed to identify potential quality issues early in the production process, allowing for timely corrective actions.

- Automated quality checks and inspections: MES systems can automate quality checks and inspections, reducing human error and ensuring consistency. They can also track the results of these checks, providing a comprehensive record of product quality.

- Complete product traceability: MES systems enable complete product traceability, allowing manufacturers to track the origin, processing steps, and handling of each product throughout its lifecycle. This traceability is essential for meeting regulatory requirements and ensuring product safety.

Cost Reduction and Resource Optimization

MES systems can significantly contribute to cost reduction and resource optimization by streamlining processes, reducing waste, and improving resource utilization.

- Reduced waste and rework: By providing real-time data and automated quality checks, MES systems help minimize production errors, reducing waste and rework. This translates into significant cost savings for manufacturers.

- Optimized inventory management: MES systems enable accurate inventory tracking and forecasting, reducing the risk of stockouts and overstocking. This optimization ensures that manufacturers have the right materials at the right time, minimizing inventory costs.

- Improved resource utilization: MES systems provide data-driven insights into resource utilization, enabling manufacturers to identify areas where resources are underutilized or overutilized. This information allows for optimized resource allocation and reduced operational costs.

MES System Implementation Process

Implementing an MES system involves a structured approach to ensure successful integration within a manufacturing environment. The process typically encompasses several distinct stages, each requiring careful planning and execution.

MES Implementation Stages

Implementing an MES system is a multifaceted process that involves several distinct stages. These stages ensure a smooth transition and successful integration of the system within the manufacturing environment.

- Project Initiation and Planning: This stage sets the foundation for the implementation. It involves defining project goals, scope, and objectives. Key activities include:

- Identifying the business needs and pain points that the MES system aims to address.

- Defining the project scope, including the manufacturing processes and departments to be covered by the MES.

- Establishing a project team with the necessary expertise and roles.

- Developing a detailed project plan, including timelines, milestones, and resource allocation.

- Requirements Gathering and Analysis: This stage involves gathering detailed information about the manufacturing processes, data requirements, and system functionalities. Key activities include:

- Conducting workshops and interviews with stakeholders from different departments to understand their needs and expectations.

- Analyzing existing data sources and processes to identify potential areas for improvement and automation.

- Documenting the detailed requirements for the MES system, including functionalities, data fields, and integration points.

- System Selection and Configuration: This stage involves choosing the right MES software solution and configuring it to meet the specific requirements of the manufacturing environment. Key activities include:

- Evaluating different MES vendors and their offerings based on functionalities, industry expertise, and pricing.

- Selecting the best-suited MES software solution that aligns with the organization’s needs and budget.

- Configuring the MES system to match the specific processes, data formats, and workflows of the manufacturing environment.

- Data Migration and Integration: This stage involves migrating existing data from legacy systems into the new MES system and integrating it with other relevant systems. Key activities include:

- Developing data migration strategies and plans to ensure data accuracy and completeness.

- Migrating data from legacy systems to the MES system, including historical data and real-time data feeds.

- Integrating the MES system with other relevant systems, such as ERP, PLM, and SCADA, to ensure data consistency and seamless workflows.

- Testing and Validation: This stage involves rigorous testing to ensure that the MES system functions as intended and meets the defined requirements. Key activities include:

- Developing test cases to cover all critical functionalities and scenarios.

- Conducting unit testing, integration testing, and user acceptance testing to validate the system’s performance.

- Identifying and resolving any bugs or issues identified during testing.

- Training and Deployment: This stage involves training users on the MES system and deploying it into the live manufacturing environment. Key activities include:

- Developing training materials and conducting user training sessions to familiarize users with the MES system.

- Deploying the MES system in phases or in a pilot environment to minimize disruption to ongoing operations.

- Providing ongoing support and assistance to users during the initial deployment and beyond.

- Maintenance and Optimization: This stage involves ongoing maintenance and optimization of the MES system to ensure its continued performance and effectiveness. Key activities include:

- Monitoring the system’s performance and identifying areas for improvement.

- Implementing regular updates and patches to address security vulnerabilities and enhance functionality.

- Optimizing the MES system to improve efficiency, reduce downtime, and enhance data accuracy.

MES Implementation Checklist

A successful MES implementation requires careful consideration of various factors. The following checklist provides a comprehensive overview of key considerations:

- Clear Project Goals and Objectives: Define the specific business goals and objectives that the MES system aims to achieve. This will provide a clear roadmap for the implementation process.

- Detailed Requirements Analysis: Conduct a thorough analysis of the manufacturing processes, data requirements, and system functionalities to ensure the MES system meets all needs.

- Proper Vendor Selection: Choose an MES vendor with proven expertise, industry experience, and a robust solution that aligns with the organization’s specific requirements.

- Effective Project Management: Establish a dedicated project team with clear roles and responsibilities to manage the implementation process effectively.

- Adequate Training and Support: Provide comprehensive training to users on the MES system and offer ongoing support to ensure successful adoption and utilization.

- Data Integrity and Security: Implement robust data management practices and security measures to ensure data integrity, confidentiality, and compliance with regulations.

- Continuous Improvement: Establish a process for ongoing monitoring, evaluation, and optimization of the MES system to ensure its effectiveness and alignment with evolving business needs.

MES System Data Management

MES systems are built on a foundation of data, and the quality of this data is crucial for the system’s effectiveness. Data integrity and accuracy are essential for making informed decisions, optimizing processes, and achieving manufacturing excellence.

Data Integrity and Accuracy

Data integrity refers to the completeness, consistency, and accuracy of the data collected and stored within the MES system. This is essential for ensuring that the information used for decision-making is reliable and trustworthy. Data accuracy is particularly important in manufacturing, as errors can lead to costly mistakes, production delays, and quality issues.

- Data validation: Implementing data validation rules helps to ensure that data entered into the system is accurate and consistent. This can involve checks for data type, range, and format, as well as comparisons against existing data to identify potential inconsistencies.

- Data cleansing: Regularly cleaning the data in the MES system is crucial for maintaining data integrity. This involves identifying and correcting errors, duplicates, and inconsistencies in the data.

- Data governance: Establishing clear data governance policies and procedures is essential for maintaining data integrity over time. This includes defining roles and responsibilities for data management, establishing data quality standards, and implementing data security measures.

Data Analytics in MES Systems

Data analytics plays a vital role in MES systems, providing insights into manufacturing operations and enabling data-driven decision-making. By analyzing data collected from various sources within the manufacturing process, companies can identify trends, patterns, and areas for improvement.

- Process optimization: Analyzing data from the MES system can help identify bottlenecks, inefficiencies, and areas for improvement in the manufacturing process. This data can be used to optimize production schedules, resource allocation, and material flow.

- Predictive maintenance: By analyzing data from sensors and equipment, MES systems can predict potential equipment failures before they occur. This allows for proactive maintenance scheduling, reducing downtime and minimizing the risk of production disruptions.

- Quality control: Analyzing data from quality inspections and tests can help identify trends in product defects and identify the root causes of quality issues. This data can be used to improve quality control procedures and reduce the number of defective products.

Data Visualization

Data visualization is an essential tool for making data insights more accessible and understandable. By presenting data in a visual format, such as charts, graphs, and dashboards, companies can gain a clearer understanding of manufacturing performance and identify key areas for improvement.

- Production performance tracking: Visualizing data on production metrics, such as output, cycle time, and efficiency, can provide a clear picture of manufacturing performance over time. This data can be used to identify trends, track progress towards goals, and identify areas for improvement.

- Real-time monitoring: Visualizing data in real-time allows for immediate insights into manufacturing operations, enabling operators to identify and address issues quickly. This can include visualizations of production status, equipment performance, and quality metrics.

- Root cause analysis: Visualizing data related to quality issues, equipment failures, and production delays can help identify the root causes of these problems. This data can be used to develop corrective actions and prevent similar issues from occurring in the future.

MES System Security and Compliance

MES systems are crucial for manufacturing operations, managing production processes, and ensuring quality. However, they also handle sensitive data and connect to other systems, making them potential targets for cyberattacks. This section will explore the security risks associated with MES systems, discuss relevant industry regulations and standards, and share best practices for ensuring their security and compliance.

Potential Security Risks Associated with MES Systems

MES systems face various security risks that could disrupt operations, compromise data, or cause financial losses.

- Unauthorized Access: Malicious actors could gain unauthorized access to MES systems, potentially modifying data, disrupting operations, or stealing sensitive information.

- Data Breaches: Data breaches can expose sensitive information, such as production schedules, customer data, and proprietary formulas, leading to reputational damage and legal consequences.

- Malware Infections: Malware can infiltrate MES systems, causing system crashes, data corruption, or even taking control of production processes.

- Denial-of-Service Attacks: These attacks can overload MES systems, making them inaccessible and disrupting production operations.

- Insider Threats: Employees with access to MES systems could misuse their privileges for malicious purposes, causing significant damage.

Industry Regulations and Standards

Several industry regulations and standards address MES system security, emphasizing the importance of protecting sensitive data and ensuring operational integrity.

- NIST Cybersecurity Framework (CSF): This framework provides a comprehensive approach to cybersecurity, offering guidance on identifying, assessing, and mitigating cyber risks. The CSF is widely adopted across industries, including manufacturing.

- ISO 27001: This international standard Artikels a framework for establishing, implementing, maintaining, and continually improving an information security management system (ISMS). ISO 27001 provides a comprehensive approach to managing information security risks.

- IEC 62443: This standard specifically focuses on industrial automation and control systems, including MES systems. It defines security requirements for different levels of industrial automation systems, ensuring secure communication and data integrity.

- FDA 21 CFR Part 11: This regulation applies to electronic records and electronic signatures in the pharmaceutical industry. It mandates specific security controls for MES systems used in pharmaceutical manufacturing to ensure data integrity and authenticity.

Best Practices for Ensuring Security and Compliance

Implementing robust security measures and adhering to industry standards are essential for protecting MES systems and ensuring compliance.

- Implement Strong Access Controls: Use multi-factor authentication, strong passwords, and role-based access control to restrict access to MES systems.

- Regularly Update Software and Systems: Patching vulnerabilities and updating software regularly is crucial to mitigate security risks.

- Network Segmentation: Isolate MES systems from other networks to limit the potential impact of a breach.

- Data Encryption: Encrypt sensitive data at rest and in transit to protect it from unauthorized access.

- Regular Security Audits: Conduct regular security audits to identify and address vulnerabilities.

- Security Awareness Training: Train employees on cybersecurity best practices to reduce the risk of insider threats.

- Incident Response Plan: Develop a comprehensive incident response plan to handle security incidents effectively and minimize damage.

MES System Selection and Evaluation

Choosing the right MES system is crucial for a successful implementation and achieving the desired benefits. This involves carefully evaluating different MES systems available in the market and selecting one that aligns with the specific needs of your manufacturing operation.

Types of MES Systems

MES systems are categorized based on their functionalities and target industries. Understanding these categories can help you narrow down your search and identify systems that are relevant to your manufacturing processes.

- Modular MES Systems: These systems offer a set of core functionalities that can be customized and extended to meet specific requirements. They are highly flexible and allow businesses to gradually implement MES features as needed.

- Integrated MES Systems: These systems provide a comprehensive suite of functionalities covering all aspects of manufacturing operations. They are designed to integrate seamlessly with existing enterprise systems, such as ERP and PLM.

- Industry-Specific MES Systems: These systems are tailored to the specific needs of particular industries, such as automotive, pharmaceuticals, or food and beverage. They offer specialized features and functionalities relevant to the unique challenges of each industry.

Criteria for Evaluating MES Systems

Evaluating the suitability of an MES system requires considering various factors that are essential for a successful implementation.

- Functionality: The system should provide the necessary features and functionalities to address your specific manufacturing requirements. This includes production scheduling, quality management, data collection, and reporting.

- Scalability: The system should be able to scale with your business growth and accommodate future expansion plans. This ensures that the system remains effective as your manufacturing operations evolve.

- Integration: The system should seamlessly integrate with your existing enterprise systems, such as ERP, PLM, and SCADA. This ensures data consistency and avoids redundancy.

- User Interface: The system should have a user-friendly interface that is easy to navigate and understand. This promotes user adoption and ensures that the system is effectively utilized by all stakeholders.

- Cost: The cost of the system, including licensing fees, implementation costs, and ongoing maintenance, should be within your budget. It’s essential to consider the total cost of ownership and the return on investment.

- Vendor Support: The vendor should provide reliable support services, including training, documentation, and technical assistance. This ensures that you can effectively utilize the system and address any issues that may arise.

MES Vendor Comparison Table

This table provides a comparison of key features and functionalities offered by different MES vendors. This information can be used to assess the suitability of each vendor’s solution for your specific needs.

| Vendor | Key Features | Functionalities | Target Industries | Pricing |

|---|---|---|---|---|

| Vendor A | Modular system, cloud-based, customizable | Production scheduling, quality management, data analysis | Automotive, electronics | Subscription-based pricing |

| Vendor B | Integrated system, on-premise, industry-specific | Production planning, inventory management, traceability | Pharmaceuticals, food and beverage | One-time license fee |

| Vendor C | Industry-specific, cloud-based, real-time data analytics | Process optimization, predictive maintenance, performance monitoring | Manufacturing, logistics | Subscription-based pricing with tiered plans |

MES System Integration and Customization

An MES system is not an isolated entity. It thrives on connectivity, exchanging data and processes with other software systems within the manufacturing ecosystem. Seamless integration and customization are key to maximizing the benefits of an MES system, ensuring it aligns perfectly with your unique manufacturing needs.

MES System Integration

Seamless integration between an MES system and other software systems is crucial for a streamlined and efficient manufacturing operation. It allows for the exchange of data, processes, and information between different systems, eliminating redundancies and creating a unified view of the manufacturing process.

- Enhanced Data Visibility: Integration allows for real-time data flow between different systems, providing a comprehensive view of the manufacturing process. This visibility helps in identifying bottlenecks, improving resource allocation, and making informed decisions.

- Reduced Errors and Improved Accuracy: Data is automatically transferred between systems, eliminating the need for manual data entry and reducing the risk of errors. This ensures data consistency and improves the accuracy of manufacturing processes.

- Streamlined Operations: Integration automates workflows and processes, reducing manual tasks and improving efficiency. This allows for faster response times, reduced downtime, and overall improved productivity.

- Improved Collaboration: Integrated systems facilitate seamless communication and collaboration between different departments, improving information sharing and decision-making.

MES System Customization

MES systems are not one-size-fits-all solutions. To truly benefit from an MES system, it needs to be tailored to the specific needs of your manufacturing environment. Customization ensures that the system meets your unique requirements, workflows, and processes.

- Process Optimization: Customization allows for the adaptation of the MES system to specific manufacturing processes, improving efficiency and productivity. This includes tailoring the system to handle specific production steps, materials, or equipment.

- Enhanced Reporting and Analytics: Customization enables the generation of tailored reports and analytics that provide valuable insights into your manufacturing operations. This helps in identifying areas for improvement and making data-driven decisions.

- Integration with Legacy Systems: Existing legacy systems can be integrated with the MES system, allowing for data sharing and process automation. This eliminates the need to replace existing systems and ensures a smooth transition.

- User Interface Personalization: The user interface can be customized to meet the specific needs of different users, ensuring ease of use and optimal user experience.

Examples of Successful MES System Integration and Customization

- Automotive Industry: An automotive manufacturer successfully integrated its MES system with its ERP system, enabling real-time tracking of production lines, inventory levels, and quality data. This improved production efficiency and reduced lead times.

- Pharmaceutical Industry: A pharmaceutical company customized its MES system to meet stringent regulatory requirements, ensuring compliance with industry standards and maintaining product quality. The system was also integrated with its laboratory information management system (LIMS) for seamless data exchange.

- Electronics Manufacturing: An electronics manufacturer integrated its MES system with its supply chain management system, allowing for better visibility of material flows and improved production planning. This resulted in reduced lead times and improved inventory management.

Future Trends in MES Systems

The manufacturing landscape is constantly evolving, driven by technological advancements and changing market demands. MES systems are at the forefront of this transformation, adapting to new technologies and playing a crucial role in enabling smart manufacturing initiatives. This section explores the emerging trends shaping the future of MES systems, focusing on the impact of technologies like IoT, AI, and cloud computing.

The Role of MES Systems in Industry 4.0

Industry 4.0, also known as the Fourth Industrial Revolution, emphasizes the integration of physical and digital systems to create intelligent and interconnected factories. MES systems are vital components of Industry 4.0, enabling real-time data collection, analysis, and decision-making.

- Enhanced Connectivity and Data Visibility: MES systems leverage IoT to connect various devices and systems within the manufacturing process, providing real-time data on production performance, equipment status, and material flow. This data visibility enables better decision-making and proactive maintenance.

- Predictive Analytics and Optimization: AI algorithms integrated into MES systems analyze historical and real-time data to identify patterns, predict potential issues, and optimize production processes. This predictive capability helps prevent downtime, improve resource allocation, and enhance overall efficiency.

- Automated Processes and Decision-Making: MES systems can automate repetitive tasks and decision-making processes, freeing up human operators for more strategic activities. This automation streamlines workflows, reduces errors, and improves overall productivity.

Closing Notes

Implementing a MES system is a strategic decision that can revolutionize a manufacturing organization. By leveraging the power of data, automation, and integration, MES systems empower manufacturers to optimize processes, enhance quality, and drive innovation. As technology continues to evolve, MES systems are poised to play an even more critical role in shaping the future of manufacturing.

MES systems are essential for streamlining manufacturing processes and optimizing efficiency. They can track everything from raw materials to finished products, ensuring smooth operations. To effectively implement a MES system, it’s crucial to have the audacity to embrace new technologies and challenge existing workflows.

With the right MES system in place, businesses can gain valuable insights into their operations and make data-driven decisions for continuous improvement.