OrCAD, a powerful electronic design automation (EDA) software suite, empowers engineers and designers to create, analyze, and manufacture electronic circuits and systems. Its comprehensive features and intuitive interface have made it a cornerstone of the electronics industry for decades, catering to a wide range of applications and industries.

Table of Contents

From schematic capture and PCB layout to simulation and analysis, OrCAD offers a complete design flow, enabling users to bring their ideas to life with efficiency and precision. Its versatility makes it suitable for a wide audience, including hobbyists, students, and professionals in various sectors such as aerospace, automotive, consumer electronics, and industrial automation.

Introduction to OrCAD

OrCAD is a comprehensive suite of electronic design automation (EDA) software tools used by engineers and designers to create, simulate, and analyze electronic circuits and systems. Developed by Cadence Design Systems, OrCAD has been a prominent player in the EDA industry for over three decades, empowering professionals across various sectors.

History of OrCAD

OrCAD’s journey began in 1985 with the founding of OrCAD Systems Corporation. The company initially focused on providing schematic capture and printed circuit board (PCB) layout software, targeting a niche market of electronic designers. In 1999, OrCAD was acquired by Cadence Design Systems, marking a significant milestone in its evolution. The acquisition integrated OrCAD’s powerful tools into Cadence’s broader EDA portfolio, expanding its reach and influence within the industry.

Key Features and Functionalities

OrCAD offers a diverse range of features and functionalities to support the entire electronic design process, from conceptualization to implementation.

Schematic Capture

OrCAD’s schematic capture tool allows designers to create and edit electronic circuit diagrams using a user-friendly graphical interface. This tool provides a comprehensive library of components, symbols, and templates, enabling efficient schematic creation and modification.

PCB Layout

OrCAD’s PCB layout tool empowers designers to create professional-grade printed circuit boards. It offers advanced routing capabilities, including automated routing algorithms, manual routing tools, and design rule checking, ensuring the creation of efficient and reliable PCBs.

Simulation

OrCAD’s simulation tools allow designers to analyze and verify the behavior of their electronic circuits before physical prototyping. These tools provide a wide range of simulation capabilities, including SPICE simulation, digital simulation, and mixed-signal simulation, enabling accurate and reliable circuit analysis.

Analysis

OrCAD’s analysis tools provide comprehensive insights into the performance and characteristics of electronic circuits. These tools offer a variety of analysis capabilities, including signal integrity analysis, power integrity analysis, and thermal analysis, helping designers optimize their designs and ensure their reliability.

Target Audience

OrCAD’s target audience encompasses a broad range of professionals involved in electronic design, including:

- Electronic Engineers: OrCAD empowers electronic engineers to design, simulate, and analyze electronic circuits and systems, ensuring the creation of innovative and reliable products.

- PCB Designers: OrCAD’s PCB layout tool provides PCB designers with the necessary tools to create high-quality and efficient printed circuit boards, meeting the demands of modern electronics.

- Researchers and Academicians: OrCAD’s powerful simulation and analysis capabilities are valuable tools for researchers and academicians engaged in electronic design and development.

- Hobbyists and Makers: OrCAD offers a user-friendly interface and comprehensive features that make it accessible to hobbyists and makers, empowering them to create their own electronic projects.

OrCAD Applications

OrCAD is a powerful electronic design automation (EDA) software suite that is widely used in various industries. Its comprehensive set of tools enables engineers to design, simulate, and analyze electronic circuits, from simple schematics to complex printed circuit boards (PCBs).

OrCAD is particularly valuable for its versatility, allowing it to be applied in numerous fields.

Industries Using OrCAD

OrCAD’s broad range of applications makes it suitable for a wide array of industries, including:

- Aerospace and Defense: OrCAD is crucial in designing and developing complex electronic systems for aerospace and defense applications. Its robust simulation and analysis capabilities ensure the reliability and performance of critical systems, such as avionics, navigation systems, and weapon control systems.

- Automotive: The automotive industry relies heavily on OrCAD for designing and developing advanced electronic systems in vehicles, including engine control units (ECUs), infotainment systems, and driver assistance systems. OrCAD’s capabilities for simulating and analyzing complex electronic circuits are vital for ensuring the safety and efficiency of these systems.

- Consumer Electronics: OrCAD is a vital tool for designing and developing a wide range of consumer electronics, from smartphones and tablets to smart home devices and wearable technology. Its user-friendly interface and comprehensive features make it suitable for both large and small consumer electronics companies.

- Industrial Automation: OrCAD plays a crucial role in designing and developing control systems for industrial automation applications. Its ability to simulate and analyze complex control systems ensures the efficiency and reliability of industrial processes, such as robotics, manufacturing, and process control.

- Medical Devices: The medical device industry uses OrCAD for designing and developing life-saving electronic systems, such as medical imaging devices, patient monitoring systems, and implantable devices. OrCAD’s ability to meet stringent regulatory requirements ensures the safety and effectiveness of these critical medical devices.

- Telecommunications: OrCAD is essential for designing and developing telecommunications infrastructure, including base stations, routers, and switches. Its comprehensive simulation and analysis capabilities enable engineers to optimize network performance and ensure reliable communication.

Specific Examples of OrCAD Applications

The versatility of OrCAD allows for diverse applications across various industries. Here are specific examples of how OrCAD is used:

- Designing a High-Performance Power Supply: OrCAD’s simulation and analysis capabilities can be used to design a high-performance power supply for a critical aerospace system. Engineers can simulate the power supply’s performance under various conditions, ensuring it meets the stringent requirements for reliability and efficiency.

- Developing an Advanced Driver Assistance System (ADAS): OrCAD can be used to design and develop a complex ADAS system for a modern car. Engineers can simulate the system’s performance in real-world scenarios, ensuring it meets the safety and performance standards for autonomous driving.

- Designing a Smart Home Hub: OrCAD can be used to design and develop a smart home hub that controls and integrates various smart devices. Engineers can simulate the hub’s communication and control protocols, ensuring seamless integration with other smart home devices.

- Developing a Medical Imaging Device: OrCAD can be used to design and develop a medical imaging device, such as a CT scanner. Engineers can simulate the device’s image processing algorithms and ensure it meets the regulatory requirements for accuracy and safety.

- Designing a High-Speed Telecommunications Router: OrCAD can be used to design and develop a high-speed telecommunications router that handles massive amounts of data. Engineers can simulate the router’s performance under heavy traffic conditions, ensuring it meets the demanding requirements for speed and reliability.

Common Types of Projects Using OrCAD

OrCAD is frequently used in various types of projects, including:

- Circuit Design: OrCAD is a powerful tool for designing and simulating electronic circuits, from simple schematics to complex PCB layouts. Its comprehensive library of components and its user-friendly interface make it suitable for a wide range of circuit design projects.

- PCB Layout: OrCAD’s PCB layout tools allow engineers to create high-quality PCB designs that meet the specific requirements of their projects. The software’s advanced routing algorithms and its comprehensive library of components ensure efficient and reliable PCB layouts.

- Simulation and Analysis: OrCAD’s simulation and analysis tools enable engineers to test and verify their designs before they are built. This helps to identify potential problems and ensure the designs meet the performance requirements.

- Verification and Testing: OrCAD’s verification and testing tools allow engineers to validate their designs and ensure they meet the required standards. The software’s comprehensive testing capabilities help to identify any potential defects or issues before the designs are released to production.

- Documentation and Reporting: OrCAD’s documentation and reporting tools allow engineers to create detailed documentation for their designs. This helps to ensure the designs are well-understood and can be easily maintained and updated.

OrCAD Design Flow

The OrCAD design flow encompasses a structured and systematic approach to creating electronic designs, from initial conceptualization to final implementation. This process involves a series of steps, each contributing to the overall integrity and success of the design.

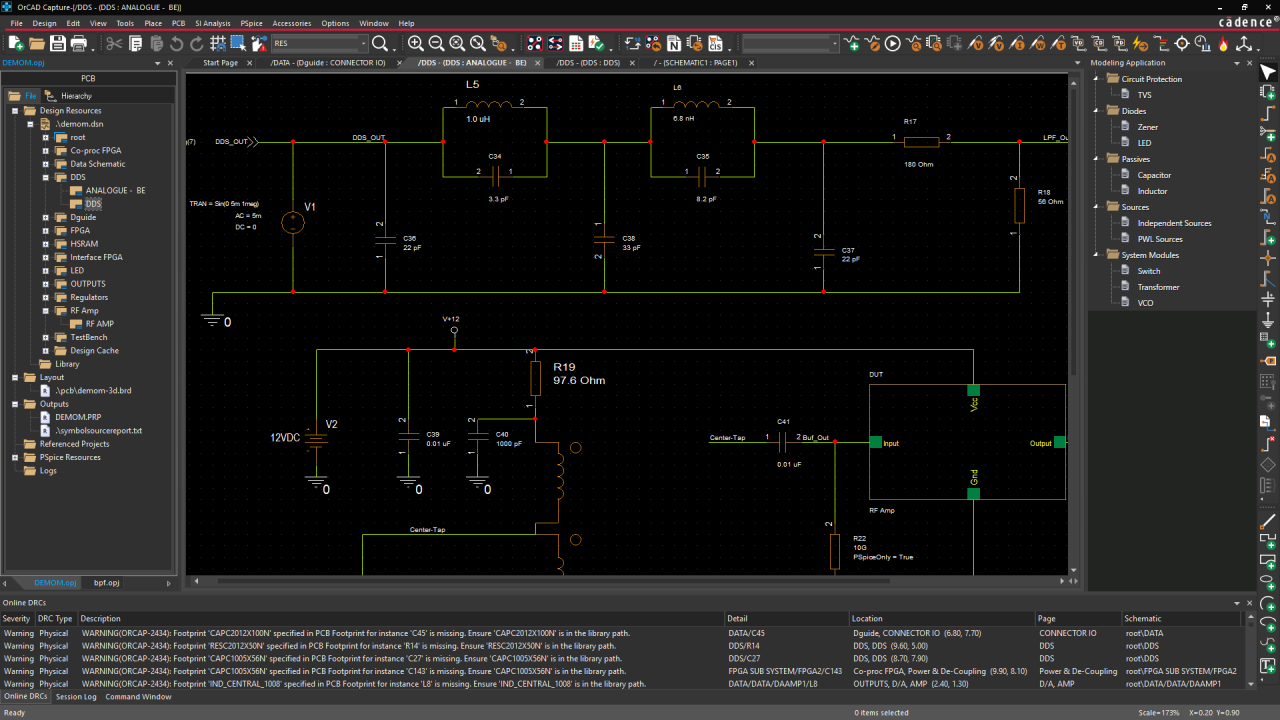

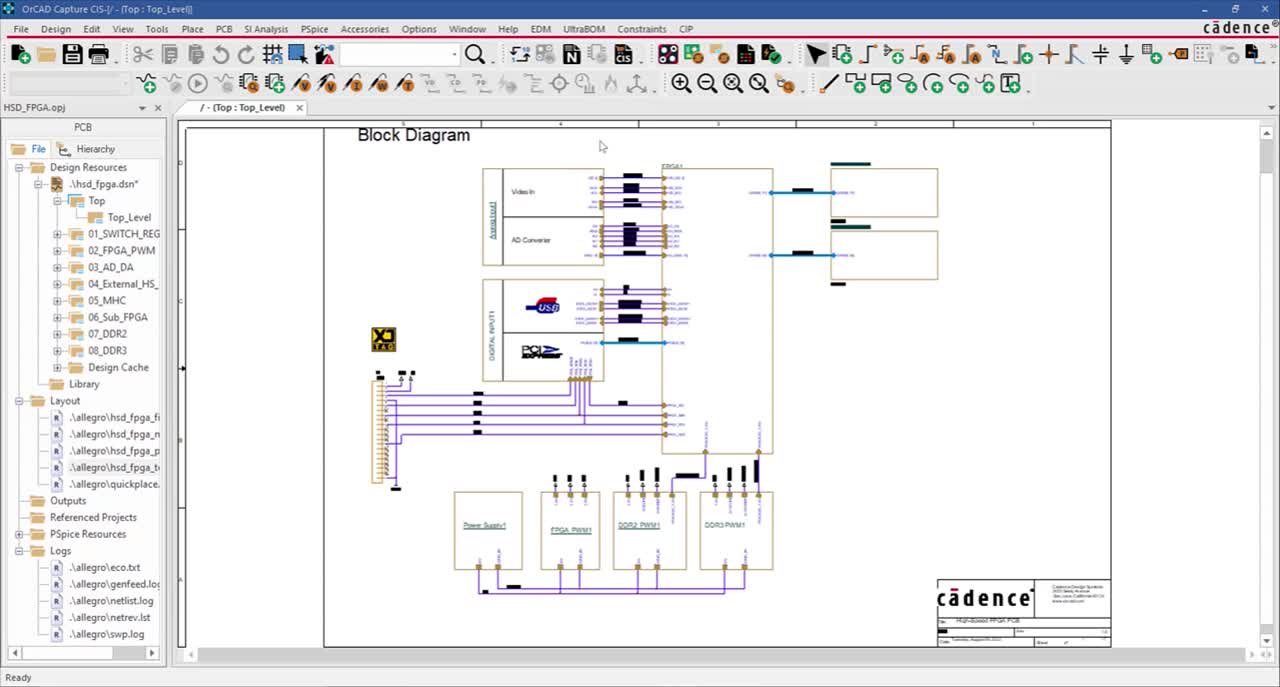

Design Entry

The initial stage involves capturing the design’s schematic, which represents the interconnection of electronic components. OrCAD provides tools like Capture CIS to create and edit schematics. The schematic captures the circuit’s topology, component values, and connections, forming the foundation for subsequent design phases.

Simulation

After capturing the schematic, simulation is crucial to verify the design’s functionality before physical implementation. OrCAD’s PSpice tool enables designers to simulate the circuit’s behavior under various conditions, analyzing parameters like voltage, current, and timing. This simulation helps identify potential issues early in the design process, allowing for corrective measures before fabrication.

Layout

Once the schematic is finalized and simulated, the layout stage involves arranging the components and connecting them on a physical board. OrCAD’s Layout editor provides tools for placing components, routing traces, and defining board layers. This stage focuses on optimizing the board’s physical design for manufacturability, signal integrity, and performance.

Verification

After layout, verification ensures that the physical design accurately reflects the schematic and meets design constraints. OrCAD offers tools for design rule checks (DRC) and electrical rule checks (ERC) to identify potential errors in the layout. This step guarantees the design’s integrity and adherence to manufacturing standards.

Fabrication

The final stage involves producing the physical printed circuit board (PCB) based on the verified layout. This stage typically involves outsourcing the fabrication process to specialized manufacturers. The manufacturer creates the PCB according to the design specifications, providing the physical realization of the electronic design.

Testing

After receiving the fabricated PCB, thorough testing is essential to ensure functionality and meet performance requirements. This stage involves applying various test procedures to verify the circuit’s operation, identify potential issues, and confirm adherence to design specifications.

OrCAD Tools and Features

The OrCAD suite encompasses a wide range of tools designed to streamline the electronic design process. These tools offer a comprehensive set of features, each serving a specific purpose in the workflow.

Capture CIS

Capture CIS is the schematic capture tool within the OrCAD suite. It provides a user-friendly interface for creating and editing schematics, enabling engineers to define the circuit’s functionality.

* Schematic Creation and Editing: Capture CIS offers intuitive tools for drawing circuit diagrams, placing components, connecting wires, and defining signal properties. It supports a wide range of components, including standard logic gates, analog circuits, and custom components.

* Hierarchical Design: Capture CIS supports hierarchical design, allowing complex circuits to be broken down into smaller, manageable blocks. This approach simplifies design management and enhances readability.

* Design Rule Checking (DRC): Capture CIS includes built-in design rule checking (DRC) to detect potential errors and inconsistencies in the schematic. This helps ensure the schematic’s accuracy and compliance with industry standards.

* Netlist Generation: Capture CIS generates a netlist, a textual representation of the circuit’s connections, which serves as input for subsequent design stages, such as simulation and layout.

PSpice

PSpice is the simulation engine within the OrCAD suite. It allows engineers to analyze the circuit’s behavior under various conditions, including different input signals, operating temperatures, and component tolerances.

* Circuit Simulation: PSpice performs various types of simulations, including DC analysis, AC analysis, transient analysis, and noise analysis. Each simulation provides insights into the circuit’s performance characteristics.

* Component Modeling: PSpice supports a wide range of component models, including standard components like resistors, capacitors, and transistors, as well as more complex models for custom devices.

* Simulation Results Visualization: PSpice provides tools for visualizing simulation results, including graphs, waveforms, and tabular data. This helps engineers interpret simulation results and identify areas for optimization.

* Optimization and Analysis: PSpice allows engineers to perform sensitivity analysis, optimization studies, and Monte Carlo simulations to evaluate the circuit’s robustness and performance under various conditions.

Layout

Layout is the PCB layout tool within the OrCAD suite. It provides a platform for creating and editing printed circuit board (PCB) designs, enabling engineers to define the physical arrangement of components and traces on the board.

* PCB Design and Layout: Layout provides a user-friendly interface for placing components, routing traces, and defining board layers. It supports various layout styles, including single-sided, double-sided, and multi-layer boards.

* Component Placement and Routing: Layout offers tools for automatic and manual component placement, routing, and trace optimization. It supports various routing algorithms, including shortest path routing, maze routing, and rip-up and reroute.

* Design Rule Checking (DRC): Layout includes DRC to detect potential errors and inconsistencies in the PCB design, ensuring compliance with manufacturing constraints and industry standards.

* Gerber File Generation: Layout generates Gerber files, a standard format for PCB fabrication, which are used to manufacture the printed circuit board.

Other OrCAD Tools

The OrCAD suite includes additional tools that complement the core design workflow:

* OrCAD Allegro: A powerful tool for high-speed and complex PCB designs, offering advanced features for routing, signal integrity analysis, and thermal management.

* OrCAD Specctra: A tool for schematic capture and simulation of high-speed digital circuits, focusing on signal integrity and timing analysis.

* OrCAD Expedition: A comprehensive tool for electronic design automation, combining schematic capture, simulation, layout, and manufacturing data management.

Comparison of OrCAD Tools

The different OrCAD tools cater to specific design requirements and complexity levels:

| Tool | Purpose | Complexity | Features |

|---|---|---|---|

| Capture CIS | Schematic capture | Basic to intermediate | Schematic creation, design rule checking, netlist generation |

| PSpice | Circuit simulation | Basic to advanced | DC, AC, transient, and noise analysis, component modeling, simulation results visualization |

| Layout | PCB layout | Basic to advanced | Component placement, routing, design rule checking, Gerber file generation |

| OrCAD Allegro | High-speed PCB design | Advanced | Advanced routing, signal integrity analysis, thermal management |

| OrCAD Specctra | High-speed digital circuit design | Advanced | Schematic capture, simulation, signal integrity and timing analysis |

| OrCAD Expedition | Comprehensive EDA | Advanced | Schematic capture, simulation, layout, manufacturing data management |

OrCAD for Schematic Capture

Schematic capture is a fundamental step in the electronic design process, forming the blueprint for your circuit. OrCAD provides a comprehensive suite of tools to create, edit, and manage electrical schematics, facilitating efficient design and documentation. This section explores the key aspects of using OrCAD for schematic capture.

Creating Schematics

OrCAD offers a user-friendly interface for creating schematics. You can start by placing components from the extensive library, which includes a wide range of devices from different manufacturers.

– Component Placement: You can easily place components on the schematic using the “Place” menu or by dragging and dropping them from the library.

– Wiring: Connections between components are established using wires, which can be drawn using the “Wire” tool. OrCAD automatically checks for errors and provides visual cues to guide you in creating valid connections.

– Net Labels: To identify specific signal paths, you can assign net labels to wires or components. Net labels help in understanding the flow of signals and facilitate the generation of netlists for PCB layout.

– Bus Structures: For handling groups of signals, OrCAD allows you to create bus structures. This simplifies the representation of complex systems and improves the readability of your schematic.

– Hierarchical Design: Large and complex circuits can be broken down into smaller, manageable blocks using hierarchical design. This approach improves organization and allows for easier modification of specific parts of the design.

Editing Schematics

Once your schematic is created, you can easily modify it using OrCAD’s editing tools.

– Component Properties: You can modify the properties of components, such as their values, references, and annotations.

– Wire Editing: You can add, delete, or modify wires to ensure the connections in your schematic are accurate.

– Moving and Rotating Components: Components can be easily moved and rotated to optimize the layout of your schematic.

– Grouping and Ungrouping: Grouping allows you to treat multiple components as a single entity, simplifying the management of complex circuits.

– Undo and Redo: OrCAD’s undo and redo functions enable you to quickly revert changes or reapply them if needed.

Tips and Techniques

Efficient schematic design is crucial for creating a clear and functional circuit. Here are some tips and techniques to enhance your schematic capture workflow in OrCAD:

– Use a Consistent Design Style: Employing a consistent design style, including component placement, wire routing, and annotation conventions, improves the readability and maintainability of your schematics.

– Leverage the Library: Utilize OrCAD’s extensive library of components, including symbols, footprints, and models. This saves time and ensures consistency in your designs.

– Create Custom Symbols: If necessary, you can create custom symbols to represent specific components or sub-circuits that are not available in the library.

– Use Hierarchical Design: Break down complex circuits into smaller blocks using hierarchical design. This improves organization and simplifies modification.

– Employ Design Rules: OrCAD provides design rules to ensure consistency and avoid potential errors. Utilize these rules to enforce specific guidelines for your schematic design.

– Utilize Schematic Annotations: Annotations, such as labels, notes, and comments, can be used to clarify the functionality and purpose of different parts of your schematic.

– Validate Your Schematic: Before proceeding to the next stage of the design process, thoroughly validate your schematic to ensure its accuracy and functionality.

OrCAD for PCB Layout

OrCAD offers a comprehensive suite of tools for designing and routing printed circuit boards (PCBs). The PCB layout process involves translating the schematic design into a physical representation of the circuit board, determining the placement of components, and defining the paths for electrical connections. This crucial stage in the electronic design process ensures the functionality and reliability of the final product.

PCB Layout Significance

PCB layout plays a vital role in electronic design, influencing factors like signal integrity, electromagnetic interference (EMI), and thermal performance. It ensures that the circuit board can function effectively while meeting performance and reliability standards.

Key Considerations for Successful PCB Layout

Successful PCB layout requires careful consideration of various factors:

- Component Placement: Strategically placing components to minimize signal path lengths, reduce crosstalk, and optimize thermal dissipation.

- Routing: Efficiently connecting components using traces and vias, ensuring proper impedance matching and minimizing signal reflections.

- Layer Stackup: Defining the number and arrangement of layers in the PCB to optimize signal routing, minimize crosstalk, and achieve desired electrical performance.

- Design Rules: Adhering to predefined rules to ensure manufacturability, electrical integrity, and signal integrity. These rules define trace widths, spacing, via sizes, and other design parameters.

- Thermal Management: Designing the PCB to dissipate heat effectively from components, preventing overheating and ensuring reliable operation.

- EMI Considerations: Minimizing electromagnetic interference by using proper shielding techniques, grounding, and layout practices to prevent noise from affecting circuit performance.

OrCAD Simulation and Analysis

OrCAD offers a suite of simulation tools that allow you to verify your circuit designs before committing to physical fabrication. These tools provide a virtual environment to analyze circuit behavior, identify potential problems, and optimize performance. This process helps to minimize costly errors, reduce design cycles, and ensure that your final product meets your specifications.

Types of Simulations in OrCAD

Simulation capabilities in OrCAD cover a wide range of applications, enabling you to analyze different aspects of your circuit design. The types of simulations available include:

- DC Analysis: This simulation determines the steady-state operating point of a circuit under different DC conditions. It helps analyze circuit behavior under various DC voltage and current scenarios. This is useful for determining voltage drops, current flows, and overall circuit performance under DC conditions.

- AC Analysis: This simulation analyzes the circuit’s response to different AC frequencies. It helps determine the circuit’s frequency response, gain, and phase shift at different frequencies. This is crucial for understanding how the circuit will perform with AC signals, like those used in audio amplifiers or filter circuits.

- Transient Analysis: This simulation analyzes the circuit’s response to time-varying signals, such as pulses, square waves, or sinusoidal waveforms. It helps understand how the circuit behaves over time, including rise and fall times, settling times, and transient responses. This is essential for analyzing circuits with dynamic behavior, such as digital circuits or control systems.

- Noise Analysis: This simulation evaluates the noise levels present in the circuit. It helps identify potential noise sources and their impact on circuit performance. This is important for circuits that require low noise levels, such as audio amplifiers or high-precision measurement systems.

- Monte Carlo Analysis: This simulation runs multiple simulations with random variations in component values. It helps determine the impact of component tolerances on circuit performance. This analysis is critical for ensuring the circuit’s reliability and robustness, especially in manufacturing where components have inherent variations.

Simulation Benefits

Simulation plays a vital role in the design process by:

- Early Error Detection: Simulation allows you to identify potential design flaws and errors before committing to physical fabrication. This reduces costly rework and delays in the design cycle.

- Performance Optimization: Simulation helps optimize circuit performance by analyzing different design parameters and their impact on the overall behavior. This enables you to fine-tune your design to achieve desired performance characteristics.

- Design Verification: Simulation provides a virtual environment to test and verify your design against specific specifications and requirements. This ensures that the final product meets the intended functionality and performance standards.

- Cost Reduction: By identifying and resolving design issues early on, simulation reduces the need for costly prototypes and revisions. This translates to significant cost savings throughout the design and development process.

Simulation Examples

Here are some examples of how simulation helps improve design quality:

- Digital Circuit Design: Simulation helps verify the functionality and timing of digital circuits. It can identify potential race conditions, timing violations, and logic errors before fabrication. This ensures the digital circuit operates correctly and meets the desired timing specifications.

- Analog Amplifier Design: Simulation can be used to analyze the frequency response, gain, and distortion of an analog amplifier. This helps optimize the design for desired performance characteristics and ensure that it meets the required signal quality standards.

- Power Supply Design: Simulation helps analyze the efficiency, regulation, and stability of a power supply circuit. It can identify potential issues with voltage drops, current fluctuations, and transient responses, ensuring the power supply operates reliably and provides the necessary voltage levels.

OrCAD Integration with Other Tools

OrCAD’s ability to integrate seamlessly with other design and manufacturing tools is a significant advantage for engineers. This integration streamlines the design process, reduces errors, and improves overall efficiency.

OrCAD’s integration capabilities allow for a smooth transition of data between different tools, ensuring consistency and accuracy throughout the design cycle.

Integration with EDA Tools

This section explores how OrCAD integrates with other Electronic Design Automation (EDA) tools. These integrations enhance the design workflow and enable engineers to leverage the strengths of various tools.

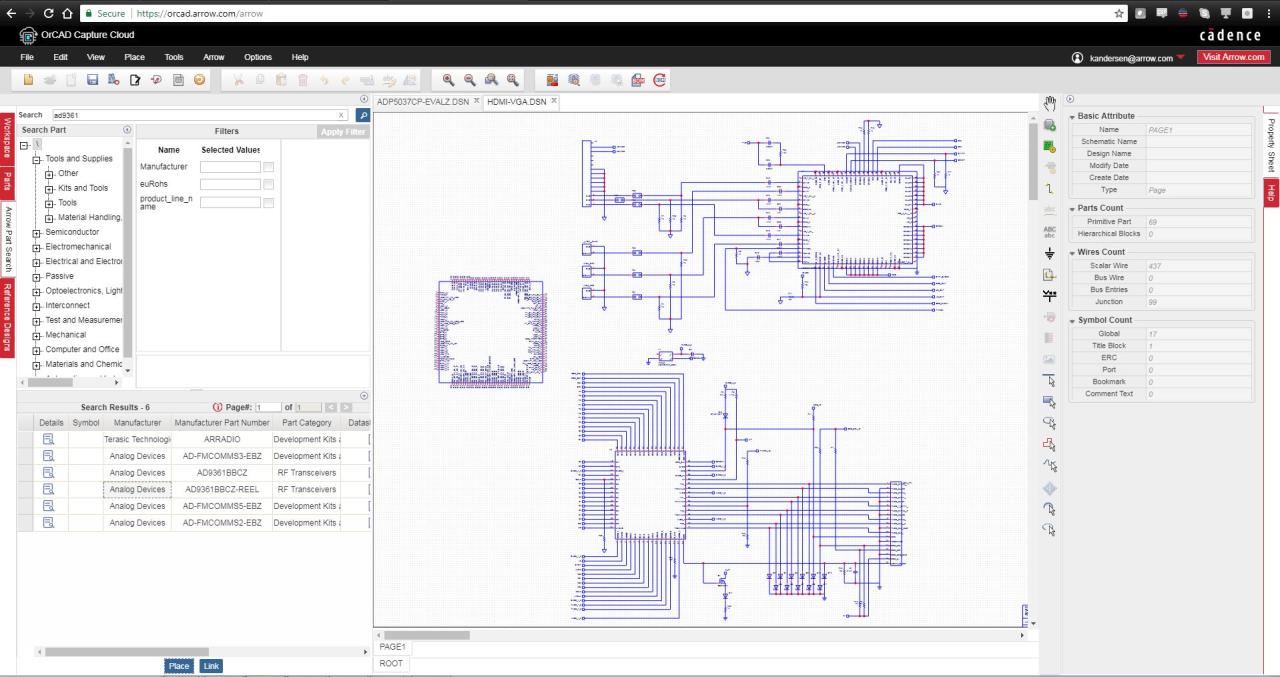

- Simulation Tools: OrCAD integrates with industry-standard simulation tools such as PSpice and Multisim. This integration allows engineers to perform circuit simulations directly within the OrCAD environment, verifying the functionality of their designs before moving to the PCB layout stage. This early verification helps identify and resolve potential design issues, saving time and resources later in the design process.

- PCB Layout Tools: OrCAD integrates seamlessly with its own PCB layout tool, Allegro. This integration enables a smooth transition of schematic data to the PCB layout environment, ensuring consistency and accuracy. The integration also allows for real-time updates between the schematic and layout, facilitating design changes and reducing the risk of errors.

- Version Control Systems: OrCAD integrates with popular version control systems like Git and SVN. This integration enables teams to collaborate on design projects effectively, track changes, and manage different versions of the design. Version control systems provide a centralized repository for all design files, ensuring that everyone is working on the latest version and minimizing the risk of conflicts.

Integration with Manufacturing Tools, Orcad

This section highlights how OrCAD integrates with tools used in the manufacturing process. This integration streamlines the manufacturing process and ensures that designs are easily translated into production-ready files.

- Gerber File Generation: OrCAD can generate Gerber files, which are standard file formats used in the PCB manufacturing process. This integration ensures that the PCB layout data is accurately translated into production-ready files, minimizing the risk of errors during manufacturing.

- Bill of Materials (BOM) Generation: OrCAD can generate a Bill of Materials (BOM), which lists all the components required for the design. This integration simplifies the procurement process by providing a comprehensive list of components and their specifications.

- Design for Manufacturing (DFM) Tools: OrCAD integrates with DFM tools that analyze the design for manufacturability. These tools identify potential issues that could arise during the manufacturing process, such as design rules violations or component placement challenges. By identifying these issues early in the design process, engineers can make necessary adjustments to ensure a smooth manufacturing process.

Benefits of Seamless Integration

This section Artikels the benefits of seamless integration between OrCAD and other design and manufacturing tools.

- Improved Efficiency: Seamless integration streamlines the design workflow by eliminating the need for manual data entry and translation between different tools. This reduces the time and effort required to complete a design project, leading to improved efficiency.

- Reduced Errors: By automating the transfer of data between different tools, integration minimizes the risk of human errors. This ensures that design information is consistent throughout the design process, reducing the need for rework and increasing the overall accuracy of the design.

- Enhanced Collaboration: Integration enables teams to collaborate effectively on design projects by providing a centralized platform for sharing design data. This promotes transparency and communication, ensuring that everyone is working on the same information and reducing the risk of misunderstandings.

OrCAD Resources and Support

OrCAD, as a comprehensive electronic design automation (EDA) suite, offers a wealth of resources and support options to help users learn, utilize, and troubleshoot the software effectively. This section delves into the various resources available, ranging from official documentation to community forums and technical support channels.

Official Documentation

OrCAD provides comprehensive documentation, encompassing user manuals, tutorials, and reference guides, to assist users in mastering the software’s functionalities. This documentation serves as a primary source of information for understanding various aspects of OrCAD, from basic operations to advanced features.

- User Manuals: These manuals offer step-by-step instructions and detailed explanations for each OrCAD tool and feature. They cover the software’s interface, design principles, and practical application scenarios.

- Tutorials: OrCAD provides interactive tutorials that guide users through specific design tasks, such as creating schematics, laying out PCBs, and performing simulations. These tutorials often use real-world examples to demonstrate practical applications.

- Reference Guides: These guides provide in-depth explanations of technical concepts, commands, and settings used within OrCAD. They are valuable for users who need to understand the underlying principles of the software.

Online Resources

Beyond the official documentation, OrCAD offers a range of online resources to facilitate learning and knowledge sharing among users. These resources provide a platform for users to connect, share experiences, and seek assistance from fellow OrCAD users and experts.

- OrCAD Community Forums: These forums allow users to engage in discussions, ask questions, and share their experiences with OrCAD. They provide a valuable platform for troubleshooting issues, seeking advice, and learning from other users.

- Knowledge Base Articles: OrCAD maintains a knowledge base containing articles and FAQs that address common issues and provide solutions. These articles offer quick access to troubleshooting tips and best practices.

- Online Tutorials and Videos: Various third-party websites and platforms offer online tutorials and videos specifically designed for OrCAD. These resources provide alternative learning paths and can supplement the official documentation.

Technical Support

For users encountering technical difficulties or needing assistance with specific design challenges, OrCAD offers dedicated technical support channels. These channels provide direct access to experienced engineers who can assist with troubleshooting, resolving issues, and providing expert guidance.

- Phone Support: OrCAD provides phone support for users who require immediate assistance or prefer a direct communication channel. This option allows users to speak with technical support representatives and receive personalized guidance.

- Email Support: Users can also submit support requests via email, providing detailed descriptions of their issues and relevant information. This option is suitable for non-urgent requests or when detailed information needs to be provided.

- Online Support Portal: OrCAD offers an online support portal where users can submit support tickets, track their progress, and access previously resolved issues. This portal provides a centralized platform for managing support requests and accessing information.

Training Options

To enhance user skills and proficiency in OrCAD, various training options are available, catering to different learning preferences and experience levels. These options range from self-paced online courses to instructor-led classroom training.

- Online Courses: OrCAD offers a variety of online courses that cover specific aspects of the software, from introductory concepts to advanced features. These courses provide flexible learning options, allowing users to learn at their own pace.

- Classroom Training: For hands-on learning and personalized instruction, OrCAD offers instructor-led classroom training sessions. These sessions provide a structured learning environment with expert guidance and practical exercises.

- Webinars and Workshops: OrCAD frequently hosts webinars and workshops on various topics related to the software. These events offer insights into industry trends, new features, and best practices for using OrCAD.

Final Summary

In conclusion, OrCAD stands as a robust and versatile EDA solution, offering a comprehensive set of tools and features to facilitate efficient and effective electronic design. Its intuitive interface, wide range of applications, and integration capabilities make it a valuable asset for engineers, designers, and anyone involved in the development of electronic products. Whether you’re a seasoned professional or a budding enthusiast, OrCAD provides the tools and resources to take your electronic design projects to the next level.

ORCAD is a powerful suite of electronic design automation (EDA) tools that have long been used by engineers for circuit design and simulation. However, with the rise of software as a service (SaaS), ORCAD has also embraced cloud-based solutions, making its capabilities accessible to a wider range of users.

This transition has opened up new possibilities for collaboration and streamlined workflows, further solidifying ORCAD’s position as a leading EDA platform.