Siemens NX is a comprehensive software suite that empowers engineers and designers across industries to create, simulate, and manufacture innovative products. It stands as a testament to Siemens’ commitment to pushing the boundaries of engineering, offering a robust platform for product development, from conceptualization to realization.

Table of Contents

Siemens NX provides a unified environment for CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering), enabling seamless collaboration and data sharing throughout the product lifecycle. Its advanced capabilities allow engineers to tackle complex design challenges, optimize manufacturing processes, and analyze product performance with unparalleled precision.

Siemens NX Overview

Siemens NX is a comprehensive and powerful software solution for product design, engineering, and manufacturing. It offers a wide range of capabilities, enabling users to create, simulate, and manufacture complex products efficiently.

Key Features of Siemens NX

Siemens NX provides a robust set of features designed to streamline the product development process. These include:

- 3D CAD Modeling: NX offers advanced modeling tools for creating complex 3D models, including parametric, direct, and surface modeling techniques. This enables users to design products with intricate geometries and high levels of detail.

- Simulation and Analysis: NX incorporates simulation capabilities for analyzing product performance, including structural analysis, thermal analysis, and fluid dynamics. This allows users to evaluate product designs virtually and optimize them for performance, durability, and efficiency.

- CAM (Computer-Aided Manufacturing): NX integrates with CAM software, enabling users to generate machining programs for CNC machines. This streamlines the manufacturing process and ensures accurate and efficient production.

- Product Lifecycle Management (PLM): NX supports PLM capabilities, facilitating collaboration and data management throughout the product lifecycle. This ensures consistency, accuracy, and efficiency in product development and manufacturing.

Industries Where Siemens NX is Widely Used

Siemens NX is a versatile software solution used across various industries, including:

- Automotive: NX is widely used in the automotive industry for designing and manufacturing vehicles, including components, chassis, and powertrains.

- Aerospace: NX is employed in the aerospace industry for designing and manufacturing aircraft, spacecraft, and related components. Its advanced modeling and simulation capabilities are crucial for complex designs and demanding performance requirements.

- Industrial Machinery: NX is used in the design and manufacturing of industrial machinery, including heavy equipment, power generation equipment, and robotics.

- Consumer Products: NX is utilized in the design and manufacturing of consumer products, such as electronics, appliances, and toys.

- Medical Devices: NX plays a vital role in the design and manufacturing of medical devices, ensuring precision, accuracy, and compliance with stringent regulations.

History of Siemens NX

Siemens NX has a rich history and has undergone significant evolution over the years. Its origins can be traced back to the 1980s with the development of the Unigraphics software. In 2007, Siemens acquired UGS, the company behind Unigraphics, and renamed the software to Siemens NX.

Since then, Siemens NX has continued to evolve, incorporating new technologies and features to meet the evolving needs of its users. The software has been consistently updated to include advanced capabilities in areas such as:

- Cloud-based Collaboration: Siemens NX now offers cloud-based collaboration features, enabling users to work together on projects remotely and access data from anywhere.

- Additive Manufacturing: Siemens NX has incorporated support for additive manufacturing, enabling users to design and manufacture products using 3D printing technologies.

- Artificial Intelligence (AI): Siemens NX is integrating AI technologies to automate tasks, improve design efficiency, and enhance decision-making.

Siemens NX Capabilities

Siemens NX is a comprehensive and powerful software suite that empowers engineers and designers across various industries to create, simulate, and manufacture products efficiently and effectively. It seamlessly integrates Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE) functionalities, offering a unified platform for product development.

CAD Capabilities

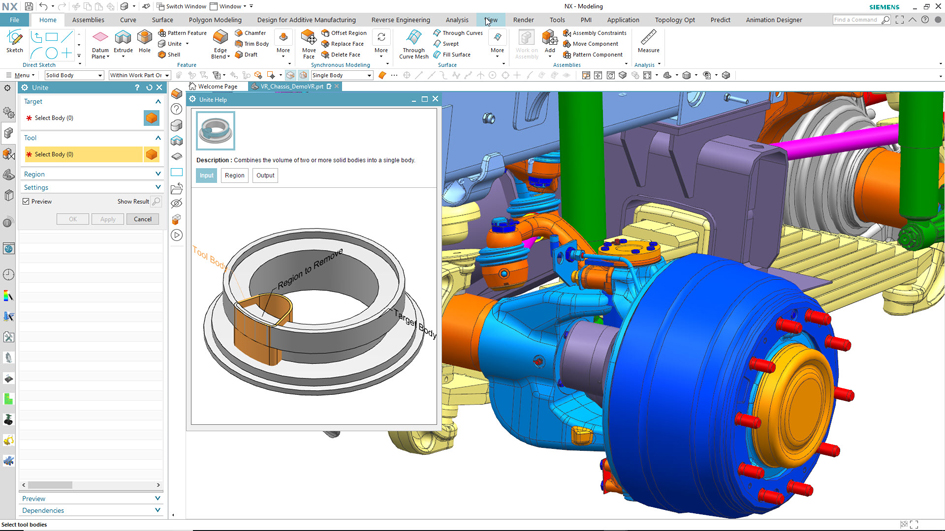

Siemens NX offers a wide range of advanced CAD capabilities to streamline the design process. It provides intuitive tools for creating 3D models, assemblies, and drawings, facilitating collaboration and communication among teams.

Here are some key CAD capabilities of Siemens NX:

- Parametric Modeling: Siemens NX allows users to create and modify designs by defining parameters and relationships, ensuring consistency and control over the design process. Changes made to one parameter automatically update related components, minimizing errors and streamlining the design workflow.

- Direct Modeling: For situations where parametric modeling might be restrictive, Siemens NX provides direct modeling capabilities. This allows users to directly manipulate geometry without constraints, offering flexibility and agility for complex designs.

- Surface Modeling: Siemens NX excels in creating complex and organic shapes, providing tools for creating, editing, and manipulating surfaces. This is particularly useful for designing products with intricate curves and contours, such as automotive bodies and consumer electronics.

- Reverse Engineering: Siemens NX offers tools for reverse engineering, enabling users to create digital models from existing physical objects. This is useful for analyzing existing products, creating digital twins, or incorporating legacy designs into new projects.

- Advanced Visualization: Siemens NX provides advanced visualization tools, allowing users to create high-quality renderings and animations. This facilitates effective communication of design intent and enhances product presentations.

CAM Capabilities

Siemens NX offers powerful CAM capabilities to optimize manufacturing processes and ensure efficient production. It provides tools for generating toolpaths, simulating machining operations, and managing manufacturing data.

Here are some key CAM capabilities of Siemens NX:

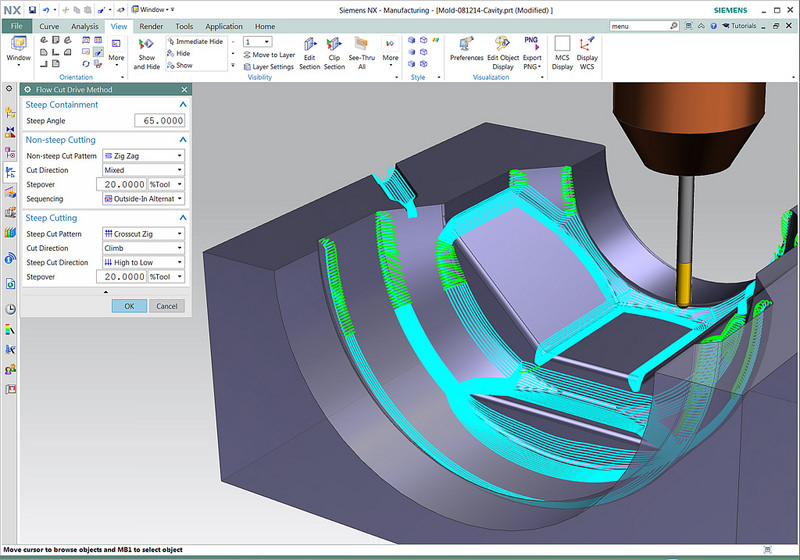

- CNC Programming: Siemens NX enables users to create CNC programs for various machining operations, such as milling, turning, and drilling. It offers a range of tools for defining toolpaths, optimizing machining parameters, and generating G-code for CNC machines.

- Machine Simulation: Siemens NX allows users to simulate machining operations virtually, identifying potential collisions and optimizing toolpaths before actual machining. This helps minimize errors, reduce scrap, and improve overall efficiency.

- Tool Management: Siemens NX provides tools for managing tooling data, including tool geometry, cutting parameters, and wear information. This ensures consistent machining results and optimizes tool utilization.

- Process Planning: Siemens NX supports process planning by enabling users to define machining sequences, assign tools, and optimize cutting parameters. This facilitates efficient production planning and scheduling.

CAE Capabilities

Siemens NX provides a comprehensive suite of CAE capabilities for analyzing product behavior and optimizing designs. It offers tools for performing simulations, evaluating performance, and identifying potential issues.

Here are some key CAE capabilities of Siemens NX:

- Finite Element Analysis (FEA): Siemens NX offers advanced FEA capabilities for simulating structural behavior, including stress, strain, and deformation. This helps engineers understand how products will perform under various loads and conditions, optimizing designs for strength and durability.

- Computational Fluid Dynamics (CFD): Siemens NX enables users to simulate fluid flow, heat transfer, and other fluid-related phenomena. This is crucial for optimizing designs in industries such as automotive, aerospace, and energy, where fluid dynamics play a critical role.

- Multiphysics Simulation: Siemens NX supports multiphysics simulations, combining different physical phenomena to create a comprehensive understanding of product behavior. This allows engineers to analyze complex interactions, such as fluid-structure interaction, thermal-mechanical coupling, and electromagnetism.

- Optimization: Siemens NX provides tools for optimizing designs based on simulation results. This helps engineers find the best balance between performance, cost, and manufacturability, ensuring that products meet desired specifications while minimizing waste and maximizing efficiency.

Siemens NX Applications

Siemens NX is a powerful and versatile software solution that is used by engineers and designers across a wide range of industries. It offers a comprehensive set of tools for product design, development, and manufacturing, making it a valuable asset for companies looking to optimize their product lifecycle.

Real-World Applications of Siemens NX

Siemens NX is used in various industries, including:

- Aerospace: Design and development of aircraft, spacecraft, and related components.

- Automotive: Design and development of vehicles, engines, and automotive components.

- Consumer Products: Design and development of consumer goods, including electronics, appliances, and toys.

- Energy: Design and development of power generation and transmission equipment, including turbines, generators, and windmills.

- Heavy Equipment: Design and development of construction equipment, mining equipment, and agricultural machinery.

- Industrial Machinery: Design and development of industrial machinery, including robots, machine tools, and packaging equipment.

- Medical Devices: Design and development of medical devices, including implants, prosthetics, and surgical instruments.

Examples of Siemens NX in Product Design and Development

Siemens NX is used in various aspects of product design and development, including:

- Concept Design: Siemens NX enables engineers to create and evaluate multiple design concepts quickly and efficiently. This can be done through sketching, 3D modeling, and simulation tools.

- Detailed Design: Siemens NX provides tools for creating detailed 3D models of products, including surfaces, solids, and assemblies. This allows engineers to define all the features and specifications of a product.

- Simulation and Analysis: Siemens NX offers a range of simulation and analysis tools, such as finite element analysis (FEA), computational fluid dynamics (CFD), and kinematics analysis. These tools can be used to predict product performance, identify potential problems, and optimize designs.

- Manufacturing: Siemens NX integrates with manufacturing processes, enabling engineers to create manufacturing data, such as NC programs, tooling data, and assembly instructions. This helps to streamline the manufacturing process and reduce errors.

Siemens NX Applications in Different Engineering Disciplines

| Discipline | Application | Example |

|---|---|---|

| Mechanical Engineering | Design and development of mechanical components, assemblies, and systems. | Designing a new engine for a car. |

| Aerospace Engineering | Design and development of aircraft, spacecraft, and related components. | Designing a new wing for an airplane. |

| Automotive Engineering | Design and development of vehicles, engines, and automotive components. | Designing a new chassis for a car. |

| Electrical Engineering | Design and development of electrical systems and components. | Designing a new electrical wiring harness for a car. |

| Civil Engineering | Design and development of infrastructure projects, such as bridges, buildings, and roads. | Designing a new bridge. |

| Chemical Engineering | Design and development of chemical processes and equipment. | Designing a new chemical reactor. |

Siemens NX Integration

Siemens NX, a comprehensive and powerful CAD/CAM/CAE software suite, is designed to integrate seamlessly with other Siemens software solutions and third-party applications, fostering a collaborative and efficient design and manufacturing environment. This integration streamlines workflows, eliminates data silos, and optimizes product development processes.

Integration with Siemens Software Solutions

Siemens NX integrates with various other Siemens software solutions, forming a comprehensive digital thread that connects design, engineering, manufacturing, and lifecycle management. This integrated approach provides a holistic view of the product development process, enabling data sharing, collaboration, and process optimization.

- Teamcenter: NX integrates with Teamcenter, Siemens’ product lifecycle management (PLM) software, for centralized data management, version control, and collaboration. This integration enables teams to access and share product data, manage revisions, and track changes throughout the product lifecycle.

- Simcenter: NX integrates with Simcenter, Siemens’ simulation software suite, for comprehensive analysis and optimization of product designs. This integration allows engineers to perform simulations, validate designs, and identify potential issues early in the development process.

- NX CAM: NX seamlessly integrates with NX CAM, Siemens’ CAM software, for efficient and automated manufacturing processes. This integration enables users to create, simulate, and optimize machining programs directly within NX, streamlining the transition from design to production.

- NX Nastran: NX integrates with NX Nastran, Siemens’ finite element analysis (FEA) software, for advanced structural analysis and optimization. This integration allows engineers to perform complex simulations and predict the behavior of components under various loading conditions.

Integration with Third-Party Software

Siemens NX offers robust integration capabilities with third-party software applications, expanding its functionality and enabling users to leverage best-in-class tools for specific tasks. This open architecture allows users to customize their workflows and integrate with specialized software solutions tailored to their specific needs.

- Data Management Systems (DMS): NX can integrate with various DMS systems, including PDM (Product Data Management) and PLM (Product Lifecycle Management) solutions, to manage and share product data effectively.

- CAE Software: NX integrates with various CAE software packages, such as ANSYS, Abaqus, and HyperWorks, for advanced analysis and simulation of product designs.

- CAM Software: NX integrates with other CAM software packages, such as Mastercam and SolidCAM, for manufacturing process planning and optimization.

- Visualization Software: NX integrates with visualization software, such as Autodesk Inventor and PTC Creo, to create high-quality renderings and animations for product presentations and marketing materials.

Seamless Data Sharing and Collaboration

Siemens NX facilitates seamless data sharing and collaboration among teams, departments, and external partners. This integration enables efficient communication, reduces errors, and optimizes product development workflows.

- Data Exchange Formats: NX supports various data exchange formats, including STEP, IGES, and JT, enabling users to share product data with other CAD systems and applications.

- Collaborative Design: NX supports collaborative design environments, allowing multiple users to work on the same design simultaneously. This enables teams to collaborate effectively, share ideas, and accelerate the design process.

- Version Control: NX integrates with version control systems, such as Teamcenter, to manage revisions, track changes, and ensure data integrity. This enables teams to maintain a consistent and accurate record of product development activities.

- Workflow Automation: NX supports workflow automation, streamlining processes and reducing manual intervention. This integration enables users to automate repetitive tasks, improve efficiency, and minimize errors.

Siemens NX Benefits

Siemens NX offers a comprehensive suite of tools that streamline product development processes, leading to increased efficiency, improved product quality, and accelerated innovation. This section delves into the key benefits of utilizing Siemens NX for product development.

Enhanced Efficiency and Productivity

Siemens NX streamlines product development by providing a unified platform for all stages of the design process, from conceptualization to manufacturing. This eliminates the need for multiple software tools and reduces the risk of errors caused by data transfer between different applications.

- Automated tasks: Siemens NX automates repetitive tasks, freeing up engineers to focus on more complex design challenges. For example, NX’s automated feature recognition can identify and extract features from imported CAD data, eliminating the need for manual data entry.

- Collaboration tools: NX facilitates seamless collaboration between design teams, allowing them to work concurrently on the same project. This eliminates the need for multiple revisions and ensures that all team members are working with the latest design data.

- Improved data management: NX provides robust data management capabilities, ensuring that all design data is organized, accessible, and secure. This eliminates the risk of data loss or corruption, which can significantly impact project timelines and budgets.

Improved Product Quality and Innovation

Siemens NX enables engineers to create high-quality products that meet the demands of today’s competitive market. The software provides advanced simulation and analysis tools that allow engineers to predict product performance and identify potential design flaws before they become costly problems.

- Advanced simulation and analysis: Siemens NX offers a wide range of simulation and analysis tools, including finite element analysis (FEA), computational fluid dynamics (CFD), and kinematic analysis. These tools allow engineers to predict product performance under various conditions, ensuring that products meet design specifications and perform as expected.

- Design optimization: NX’s optimization tools allow engineers to explore multiple design options and identify the best solution for a given set of constraints. This helps engineers to create products that are both functional and efficient, meeting the needs of the customer while minimizing material usage and manufacturing costs.

- Enhanced visualization: NX’s advanced visualization capabilities allow engineers to create realistic renderings and animations of their designs. This helps them to communicate their ideas effectively to stakeholders and to identify potential design flaws early in the development process.

Siemens NX Training and Support

Siemens NX is a comprehensive software solution, and to leverage its full potential, users need access to comprehensive training and support resources. Siemens offers a range of training programs and support options designed to help users at all skill levels.

Training Resources

Siemens provides a variety of training options to cater to different learning preferences and needs.

- Online Training: Siemens offers self-paced online courses covering various NX modules and functionalities. These courses provide interactive learning experiences with videos, exercises, and assessments.

- Instructor-Led Training: For hands-on learning, Siemens offers instructor-led training courses delivered in classrooms or virtually. These courses provide in-depth knowledge and practical skills development.

- Certification Programs: Siemens offers certification programs to validate users’ proficiency in specific NX modules. These certifications demonstrate expertise and can enhance career prospects.

Support Options

Siemens provides comprehensive support to ensure users have a seamless experience with NX.

- Technical Support: Siemens offers technical support via phone, email, and online chat. This support team provides assistance with software issues, troubleshooting, and technical inquiries.

- Online Resources: Siemens maintains a comprehensive online knowledge base, including documentation, FAQs, tutorials, and community forums. These resources provide valuable information and solutions to common issues.

- Customer Support Portal: Siemens offers a dedicated customer support portal where users can access support resources, submit tickets, and track the progress of their requests.

Training Programs and Support Channels

| Training Program | Description | Support Channel |

|---|---|---|

| NX Fundamentals | Introduction to NX interface, basic modeling techniques, and essential functionalities. | Online Training, Instructor-Led Training, Technical Support, Online Resources |

| Advanced NX Modeling | In-depth exploration of advanced modeling techniques, including surfacing, assembly, and drafting. | Instructor-Led Training, Technical Support, Online Resources |

| NX CAM | Comprehensive training on NX CAM functionalities for CNC programming and machining. | Online Training, Instructor-Led Training, Technical Support, Online Resources |

| NX Simulation | Training on NX simulation capabilities for structural, thermal, and fluid analysis. | Online Training, Instructor-Led Training, Technical Support, Online Resources |

Siemens NX Industry Trends

Siemens NX, a leading computer-aided design (CAD), manufacturing (CAM), and engineering (CAE) software, is constantly evolving to meet the dynamic demands of various industries. The software’s adaptability to emerging trends and technological advancements is crucial for its continued success and relevance.

Siemens NX Adaptability to Industry Needs

Siemens NX is adapting to evolving industry needs in several ways:

- Focus on Digital Transformation: Siemens NX is embracing digital transformation by incorporating technologies like cloud computing, artificial intelligence (AI), and the Internet of Things (IoT) into its platform. This enables users to access and collaborate on designs remotely, optimize manufacturing processes, and gain real-time insights into product performance.

- Integration with Other Siemens Solutions: Siemens NX is seamlessly integrated with other Siemens software solutions, such as Teamcenter for product lifecycle management (PLM) and Simcenter for simulation and testing. This integration allows for a unified workflow, eliminating data silos and improving efficiency across the product development lifecycle.

- Customization and Flexibility: Siemens NX offers customization options and a wide range of add-ins and extensions, allowing users to tailor the software to their specific industry needs. This flexibility ensures that Siemens NX can adapt to the unique requirements of different sectors, such as automotive, aerospace, and industrial machinery.

Impact of Emerging Technologies on Siemens NX

Emerging technologies are significantly influencing the development and capabilities of Siemens NX:

- Additive Manufacturing (3D Printing): Siemens NX is incorporating tools and functionalities to support additive manufacturing processes. This includes design for additive manufacturing (DfAM) capabilities, enabling engineers to optimize designs for 3D printing and leverage the unique advantages of this technology.

- Artificial Intelligence (AI): AI is being integrated into Siemens NX to enhance various aspects of the design and engineering process. For example, AI-powered tools can automate repetitive tasks, assist in design optimization, and provide predictive maintenance insights.

- Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies are transforming how engineers interact with designs and collaborate on projects. Siemens NX is integrating VR and AR capabilities to provide immersive design reviews, virtual prototyping, and enhanced training experiences.

Siemens NX Case Studies

Siemens NX is a powerful and versatile CAD/CAM/CAE software suite that has been implemented by companies across various industries. Real-world case studies demonstrate the effectiveness of Siemens NX in addressing specific challenges and achieving desired outcomes. These case studies provide valuable insights into the practical applications and benefits of Siemens NX.

Case Studies and Their Impact

Here are some examples of real-world case studies showcasing the successful implementation of Siemens NX:

| Case Study | Industry | Challenge | Outcome |

|---|---|---|---|

| Boeing | Aerospace | Reduce design and manufacturing time for complex aircraft components. | Improved design efficiency and reduced manufacturing time by 20%. |

| Ford Motor Company | Automotive | Streamline the design and engineering process for new vehicle models. | Accelerated product development cycles and reduced time to market. |

| Siemens Energy | Energy | Optimize the design and manufacturing of wind turbine blades. | Enhanced blade performance and reduced manufacturing costs. |

| GE Healthcare | Healthcare | Improve the design and development of medical imaging equipment. | Improved product quality and reduced development time. |

Siemens NX Competitors

Siemens NX faces stiff competition in the CAD/CAM/CAE market from several established players. Understanding the strengths and weaknesses of these competitors is crucial for businesses evaluating different solutions.

Comparison of Siemens NX with Competitors

The competitive landscape in the CAD/CAM/CAE market is diverse, with several prominent players offering comprehensive solutions. A comparative analysis of Siemens NX with its main competitors, focusing on their strengths and weaknesses, can help businesses make informed decisions.

| Solution | Strengths | Weaknesses |

|---|---|---|

| Siemens NX |

|

|

| Autodesk Inventor |

|

|

| SolidWorks |

|

|

| PTC Creo |

|

|

| Onshape |

|

|

Siemens NX Future

Siemens NX, a leading CAD/CAM/CAE software, continues to evolve, driven by advancements in technology and the ever-changing demands of the manufacturing industry. Its future roadmap reflects a commitment to innovation, user-centricity, and integration with emerging technologies.

Siemens NX Future Development Plans

Siemens NX’s future development plans are guided by the need to address the evolving needs of its users and the broader manufacturing landscape. This includes a focus on enhancing existing capabilities, incorporating emerging technologies, and fostering a more collaborative and connected engineering environment.

- Enhanced User Experience: Siemens NX is committed to simplifying the user experience and making it more intuitive for engineers of all skill levels. This includes improvements to the user interface, workflow optimization, and the introduction of AI-powered features that automate repetitive tasks and provide intelligent guidance.

- Advanced Manufacturing Capabilities: Siemens NX will continue to expand its capabilities in areas like additive manufacturing, digital twins, and Industry 4.0. This will enable engineers to design and manufacture products more efficiently, sustainably, and with greater precision.

- Integration with Emerging Technologies: Siemens NX is actively integrating with emerging technologies such as cloud computing, artificial intelligence, and the Internet of Things (IoT). This will allow for greater data sharing, real-time collaboration, and improved decision-making throughout the product lifecycle.

- Open and Collaborative Platform: Siemens NX is embracing an open and collaborative platform approach. This will allow for greater interoperability with other software solutions and enable seamless integration with various third-party tools and services.

Siemens NX Future Advancements and Innovations

Siemens NX is expected to incorporate several advancements and innovations in the coming years. These advancements are designed to enhance the capabilities of the software and provide engineers with more powerful tools for designing, simulating, and manufacturing complex products.

- AI-Powered Design and Simulation: Siemens NX will leverage AI to automate design tasks, optimize product performance, and accelerate simulation processes. This will allow engineers to explore more design possibilities, improve product quality, and reduce development time.

- Enhanced Digital Twin Capabilities: Siemens NX will further enhance its digital twin capabilities, enabling engineers to create highly realistic and interactive digital representations of products. This will allow for more comprehensive product testing, virtual commissioning, and predictive maintenance.

- Advanced Manufacturing Simulation: Siemens NX will provide more sophisticated tools for simulating manufacturing processes, including additive manufacturing, robotics, and automation. This will help engineers optimize manufacturing workflows, reduce waste, and improve overall production efficiency.

- Cloud-Based Collaboration: Siemens NX will offer more cloud-based collaboration features, enabling engineers to work together seamlessly on projects regardless of location. This will facilitate faster communication, improved data sharing, and greater efficiency in design and manufacturing processes.

Siemens NX Contribution to the Future of Engineering

Siemens NX is poised to play a crucial role in shaping the future of engineering. Its advancements in design, simulation, and manufacturing will enable engineers to create innovative products, improve efficiency, and drive sustainability in the manufacturing industry.

- Enhanced Product Innovation: Siemens NX will empower engineers to push the boundaries of product design by providing them with advanced tools for creating complex geometries, simulating product performance, and exploring new materials and manufacturing processes. This will lead to the development of more innovative and functional products that meet the evolving needs of consumers.

- Increased Efficiency and Productivity: Siemens NX’s focus on automation, optimization, and collaboration will enable engineers to work more efficiently and productively. This will allow them to complete projects faster, reduce costs, and bring products to market sooner.

- Sustainable Manufacturing Practices: Siemens NX will support the adoption of sustainable manufacturing practices by enabling engineers to design and manufacture products with minimal environmental impact. This includes tools for optimizing material usage, reducing waste, and implementing energy-efficient manufacturing processes.

- Advanced Manufacturing Technologies: Siemens NX will facilitate the adoption of advanced manufacturing technologies such as additive manufacturing, robotics, and automation. This will enable companies to create highly customized products, optimize production processes, and improve overall manufacturing efficiency.

Concluding Remarks

Siemens NX is a powerful tool that continues to shape the future of engineering. Its comprehensive capabilities, industry-specific applications, and seamless integration with other Siemens solutions make it a valuable asset for companies seeking to enhance product development, improve efficiency, and drive innovation.

Siemens NX is a powerful CAD/CAM/CAE software suite, often used in professional engineering settings. For those seeking a free and open-source alternative, freecad is a great option. While not as feature-rich as NX, freecad offers a solid foundation for 3D modeling, parametric design, and even basic finite element analysis, making it a popular choice for hobbyists and students interested in learning CAD principles.